Высевающая линия для разбрасывателя лотка с сеялкой для барабанов и сопел

Русский

Русский  Английский

Английский

Описание:

Visser tray filling and seeding line

This tray seeding line consists of:

- Visser EC-40 tray filling machine

- Dibbler (pushes vertical one tray at a time)

- Visser PLS2 40/3000 double trays seeder, with

- Drum seeder

- Granette nozzle seeder (for more difficult seeds)

- Dibbler

- Visser VT-600 vermiculite spreader

- Visser watering unit

- Roller conveyor

Visser tray filling machine

The soil hopper is supplying the soil to the elevator by means of a conveyor which is adjustable in speed. The elevator brings the soil up to the filling head. Inside the filling head a rotor with rubber flaps is pushing the soil into the tray. This component of the machine is the heart of the effectivity: it creates a remarkable uniformity for trays and pots in trays. By changing the speed of the rotor and the height of the filling head the soil density can be adjusted. The hopper brings soil back to the soil hopper for re-usage. Year of production

Dibbler

Visser Granette nozzle seeder

- Easy adjustable for different kind of trays

Vermiculite spreader

The machine can be adjusted for other tray sizes. For this other dibblers and seeding drums are required.

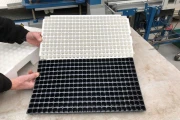

Optional: 288 cell tray with inlay tray

- 288 cells 12 x 24

- Manufacturer: DW Plastics NV

- Approximately 2000 pieces of PVC (white) (used)

- Approximately 3000 pieces of inlay tray (black) (new) 7.6 cc

Технические спецификации:

| Модель: | PLS2: Granette & Speed Rouline |

Description:

Visser tray filling and seeding line

This tray seeding line consists of:

- Visser EC-40 tray filling machine

- Dibbler (pushes vertical one tray at a time)

- Visser PLS2 40/3000 double trays seeder, with

- Drum seeder

- Granette nozzle seeder (for more difficult seeds)

- Dibbler

- Visser VT-600 vermiculite spreader

- Visser watering unit

- Roller conveyor

Visser tray filling machine

The soil hopper is supplying the soil to the elevator by means of a conveyor which is adjustable in speed. The elevator brings the soil up to the filling head. Inside the filling head a rotor with rubber flaps is pushing the soil into the tray. This component of the machine is the heart of the effectivity: it creates a remarkable uniformity for trays and pots in trays. By changing the speed of the rotor and the height of the filling head the soil density can be adjusted. The hopper brings soil back to the soil hopper for re-usage. Year of production

Dibbler

Visser Granette nozzle seeder

- Easy adjustable for different kind of trays

Vermiculite spreader

The machine can be adjusted for other tray sizes. For this other dibblers and seeding drums are required.

Optional: 288 cell tray with inlay tray

- 288 cells 12 x 24

- Manufacturer: DW Plastics NV

- Approximately 2000 pieces of PVC (white) (used)

- Approximately 3000 pieces of inlay tray (black) (new) 7.6 cc

Высевающая линия для разбрасывателя лотка с сеялкой для барабанов и сопел

К сожалению, Высевающая линия для разбрасывателя лотка с сеялкой для барабанов и сопел продана..

Хотите ли вы получать информацию, когда аналогичная Наполнители кассет торфом появится в продаже? Заполните свои данные здесь.

Продал

Пожалуйста свяжитесь Tatiana

Мы будем рады вам помочь. Наши консультанты к вашим услугам.

(7).jpg?resolution=100x100&quality=100&type=webp) Позвоните нам: +31 180 632 088

Позвоните нам: +31 180 632 088Описание:

Visser tray filling and seeding line

This tray seeding line consists of:

- Visser EC-40 tray filling machine

- Dibbler (pushes vertical one tray at a time)

- Visser PLS2 40/3000 double trays seeder, with

- Drum seeder

- Granette nozzle seeder (for more difficult seeds)

- Dibbler

- Visser VT-600 vermiculite spreader

- Visser watering unit

- Roller conveyor

Visser tray filling machine

The soil hopper is supplying the soil to the elevator by means of a conveyor which is adjustable in speed. The elevator brings the soil up to the filling head. Inside the filling head a rotor with rubber flaps is pushing the soil into the tray. This component of the machine is the heart of the effectivity: it creates a remarkable uniformity for trays and pots in trays. By changing the speed of the rotor and the height of the filling head the soil density can be adjusted. The hopper brings soil back to the soil hopper for re-usage. Year of production

Dibbler

Visser Granette nozzle seeder

- Easy adjustable for different kind of trays

Vermiculite spreader

The machine can be adjusted for other tray sizes. For this other dibblers and seeding drums are required.

Optional: 288 cell tray with inlay tray

- 288 cells 12 x 24

- Manufacturer: DW Plastics NV

- Approximately 2000 pieces of PVC (white) (used)

- Approximately 3000 pieces of inlay tray (black) (new) 7.6 cc

Почему вы выбираете машины, бывшие в употреблении?

- Быстрая поставка

- Низкая стоимости приобретения

- Более низкая амортизация

- Такие же функции, как и у новых машин

Машины для Комнатные растения

Вы заинтересовались этой машиной?

Предлагаем вам несколько возможностей:

Подать заявку на торговое предложение

Прошу прислать мне торговое предложение на данную машину.

Я хочу добавить эту машину к моей заявке и продолжить просмотр ассортимента.

Выберите этот вариант, если вы хотите получить торговое предложение на несколько машин.

У меня есть вопросы по поводу этой конкретной машины.

Меня заинтересовала данная машина, но сначала я хочу задать вопрос.

Подать заявку на торговое предложение (

Подать заявку на торговое предложение (

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)