Concept Engineers optikai osztályozó gép sárgarépa hibaosztályozására

Magyar

Magyar  Angol

Angol

Érvek és ellenérvek

- Extra versenyképes áron

Leírás:

Optimum Sorting Concept Engineers optical grading machine for defect grading on carrots.

Complete with length / chunk grader

This machine is used to sort defect on carrots. But it can also be used to sort other products.

The model Focus from Concept Engineers is an optical sorter especially developed to sort products with various optical deficiencies. Discoloration, deformation and foreign objects are detected and accuratelyremoved from the product flow. The Focus can be used for fresh / dried or frozen potato product, vegetables, fruit as well as seafood. Use of the Focus will lead to quality improvement of your final product, but also to lower and more predictable production costs.

Capacity

The capacity is maximum 15,000 kg of carrots per hour on the machine (good and bad), depending on the size of the carrots with a defect level of up to 30 % failure.

Principle of operation

The carrots are fed to the conveyor via an input vibrating screen. This distributes the product evenly (in width and length direction), while this vibrating screen can be used at the same time as a fracture / length sorter.

The product comes through a chute on the white inspecion belt of the grading machine. The purpose of this chute is to feed the carrots in the correct speed to the sorting machine. Because of this the product will remain still on the inspection belt.

The Concept Engineers belt sorter is equipped with two B / W CCD line scan cameras and features both color and shape recognition.

Simple to operate

Through a color touch screen this machine is very simple to operate. The set values are stored in a sorting program.

Special software developed for sorting carrots. To check the grading results, the machine is equipped with a static program (pie chart), which controls the number of graded carrots at various set-ups.

The following points distinguish the optical sorting of Concept Engineers from its competitors:

- Easy to install by only connecting electrics, air and water.

- Cleaning friendly by using lots of sheet material and minimize horizontal surfaces where product can accumulate on.

- Use of many on the market available componets, such as belt, bearings, motor, lamps and other electrical items.

- Quickly and easily replaceable parts, such as lights, cameras, belt and motor.

- Industrial computer composed of a high-speed processor for control of the machine. And a local processor system for the cameras and processing the camera signals.

- Touch screen control panel with 'frame grab' feature and many control options. However, simple to operate for the operating staff.

- The minimum response time of the discharge valves is 2 milliseconds.

Technical specifications

Frame

Construction of stainless steel 304.

Dimensions :

- Length : 4.383 mm

- Width : 2.646 mm

- Height : 2.900 mm

- Inspection belt width : 1.800 mm Netto

Water is needed for cleaning the belt (15 liters per minute, feed line for at least 3 /4 ")

Water pressure up to 2 bar, at least one bar

Belt speed control via frequency inverter

Airconditioner for constant temperature camera and computer cabinet

Power consumption : 8.5 kW

Power supply : 400 V AC, 3 phase + earth + neutral , 50 Hz

Computer Systems

Industrial setup

The system has an interface card for each camera with local processor

Graphic color control panel with IR touch screen operation (IP55)

Industrial computer enclosure with filtered fans

Cameras

4 pcs B / W CCD line scan type

Electronic compensation for offset drift of the camera signal

Software "offset " and " gain" settings

Software control of the camera signal

Software

Possible settings with " frame grag " and conventional method

Settings for color and shape recognition :

Color Recognition :

- In relative size of the head of the carrot

- Absolute spot size for the remainder of the carrot

Shape Recognition :

- Minimum and maximum length

- Length / width ratio

- Curvation

Product set-ups (pre-programmed)

Discharge unit

Electronic integrated in discharge unit

Air must be dried and 0.1 micron particles filtered, 3 degrees C dew point and 0.08 ppm ( 0.1 mg/m3 ) oil filtration

Air 6 bar minimum; consumes 1800 l / min at 30 % defect level

Air supply line at least 1 1/2 "

Lights

High frequency fluorescent lighting

IR illumination below the belt

Special reflectors for increased light output

Built- in camera body (less pollution)

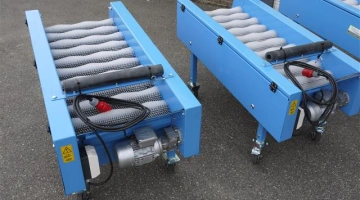

Input vibrating screen

Dimensions:

- Length : 2,650 mm

- Width : 2,360 mm

- Height : 2,160 mm

Powered by unbalanced motors

Control cabinet et electric brake unit

Chute / ramp, equipped with special system to release the carrots on the belt

New price approx Euro 260.000,=

* Please ask for our very special sales price

Műszaki specifikációk::

| Típus: | Focus 1800 |

| Kiadási év: | 2012 |

| Kapacitás: | 15.000 kg / hour |

| Méretek: | 439 cm x 265 cm x 290 cm (hossz x szélesség x magasság) |

Description:

Optimum Sorting Concept Engineers optical grading machine for defect grading on carrots.

Complete with length / chunk grader

This machine is used to sort defect on carrots. But it can also be used to sort other products.

The model Focus from Concept Engineers is an optical sorter especially developed to sort products with various optical deficiencies. Discoloration, deformation and foreign objects are detected and accuratelyremoved from the product flow. The Focus can be used for fresh / dried or frozen potato product, vegetables, fruit as well as seafood. Use of the Focus will lead to quality improvement of your final product, but also to lower and more predictable production costs.

Capacity

The capacity is maximum 15,000 kg of carrots per hour on the machine (good and bad), depending on the size of the carrots with a defect level of up to 30 % failure.

Principle of operation

The carrots are fed to the conveyor via an input vibrating screen. This distributes the product evenly (in width and length direction), while this vibrating screen can be used at the same time as a fracture / length sorter.

The product comes through a chute on the white inspecion belt of the grading machine. The purpose of this chute is to feed the carrots in the correct speed to the sorting machine. Because of this the product will remain still on the inspection belt.

The Concept Engineers belt sorter is equipped with two B / W CCD line scan cameras and features both color and shape recognition.

Simple to operate

Through a color touch screen this machine is very simple to operate. The set values are stored in a sorting program.

Special software developed for sorting carrots. To check the grading results, the machine is equipped with a static program (pie chart), which controls the number of graded carrots at various set-ups.

The following points distinguish the optical sorting of Concept Engineers from its competitors:

- Easy to install by only connecting electrics, air and water.

- Cleaning friendly by using lots of sheet material and minimize horizontal surfaces where product can accumulate on.

- Use of many on the market available componets, such as belt, bearings, motor, lamps and other electrical items.

- Quickly and easily replaceable parts, such as lights, cameras, belt and motor.

- Industrial computer composed of a high-speed processor for control of the machine. And a local processor system for the cameras and processing the camera signals.

- Touch screen control panel with 'frame grab' feature and many control options. However, simple to operate for the operating staff.

- The minimum response time of the discharge valves is 2 milliseconds.

Technical specifications

Frame

Construction of stainless steel 304.

Dimensions :

- Length : 4.383 mm

- Width : 2.646 mm

- Height : 2.900 mm

- Inspection belt width : 1.800 mm Netto

Water is needed for cleaning the belt (15 liters per minute, feed line for at least 3 /4 ")

Water pressure up to 2 bar, at least one bar

Belt speed control via frequency inverter

Airconditioner for constant temperature camera and computer cabinet

Power consumption : 8.5 kW

Power supply : 400 V AC, 3 phase + earth + neutral , 50 Hz

Computer Systems

Industrial setup

The system has an interface card for each camera with local processor

Graphic color control panel with IR touch screen operation (IP55)

Industrial computer enclosure with filtered fans

Cameras

4 pcs B / W CCD line scan type

Electronic compensation for offset drift of the camera signal

Software "offset " and " gain" settings

Software control of the camera signal

Software

Possible settings with " frame grag " and conventional method

Settings for color and shape recognition :

Color Recognition :

- In relative size of the head of the carrot

- Absolute spot size for the remainder of the carrot

Shape Recognition :

- Minimum and maximum length

- Length / width ratio

- Curvation

Product set-ups (pre-programmed)

Discharge unit

Electronic integrated in discharge unit

Air must be dried and 0.1 micron particles filtered, 3 degrees C dew point and 0.08 ppm ( 0.1 mg/m3 ) oil filtration

Air 6 bar minimum; consumes 1800 l / min at 30 % defect level

Air supply line at least 1 1/2 "

Lights

High frequency fluorescent lighting

IR illumination below the belt

Special reflectors for increased light output

Built- in camera body (less pollution)

Input vibrating screen

Dimensions:

- Length : 2,650 mm

- Width : 2,360 mm

- Height : 2,160 mm

Powered by unbalanced motors

Control cabinet et electric brake unit

Chute / ramp, equipped with special system to release the carrots on the belt

New price approx Euro 260.000,=

* Please ask for our very special sales price

Technical specifications:

| Model: | Focus 1800 |

| Year: | 2012 |

| Capacity: | 15.000 kg / hour |

| Dimensions: | 439 cm x 265 cm x 290 cm (length x width x height) |

Concept Engineers optikai osztályozó gép sárgarépa hibaosztályozására

Sajnos ez a Concept Engineers optikai osztályozó gép sárgarépa hibaosztályozására most elkelt.

Szeretne értesülni, ha elérhető lesz egy hasonló Sárgarépa betakarítók? Itt töltse ki adatait.

Eladott

Kérem, hívjon Tatiana

Boldogan segítünk Önnek. Ügyfélszolgálati munkatársaink várják a hívását.

(7).jpg?resolution=100x100&quality=100&type=webp) Hívjon minket: +31 180 632 088

Hívjon minket: +31 180 632 088Leírás:

Optimum Sorting Concept Engineers optical grading machine for defect grading on carrots.

Complete with length / chunk grader

This machine is used to sort defect on carrots. But it can also be used to sort other products.

The model Focus from Concept Engineers is an optical sorter especially developed to sort products with various optical deficiencies. Discoloration, deformation and foreign objects are detected and accuratelyremoved from the product flow. The Focus can be used for fresh / dried or frozen potato product, vegetables, fruit as well as seafood. Use of the Focus will lead to quality improvement of your final product, but also to lower and more predictable production costs.

Capacity

The capacity is maximum 15,000 kg of carrots per hour on the machine (good and bad), depending on the size of the carrots with a defect level of up to 30 % failure.

Principle of operation

The carrots are fed to the conveyor via an input vibrating screen. This distributes the product evenly (in width and length direction), while this vibrating screen can be used at the same time as a fracture / length sorter.

The product comes through a chute on the white inspecion belt of the grading machine. The purpose of this chute is to feed the carrots in the correct speed to the sorting machine. Because of this the product will remain still on the inspection belt.

The Concept Engineers belt sorter is equipped with two B / W CCD line scan cameras and features both color and shape recognition.

Simple to operate

Through a color touch screen this machine is very simple to operate. The set values are stored in a sorting program.

Special software developed for sorting carrots. To check the grading results, the machine is equipped with a static program (pie chart), which controls the number of graded carrots at various set-ups.

The following points distinguish the optical sorting of Concept Engineers from its competitors:

- Easy to install by only connecting electrics, air and water.

- Cleaning friendly by using lots of sheet material and minimize horizontal surfaces where product can accumulate on.

- Use of many on the market available componets, such as belt, bearings, motor, lamps and other electrical items.

- Quickly and easily replaceable parts, such as lights, cameras, belt and motor.

- Industrial computer composed of a high-speed processor for control of the machine. And a local processor system for the cameras and processing the camera signals.

- Touch screen control panel with 'frame grab' feature and many control options. However, simple to operate for the operating staff.

- The minimum response time of the discharge valves is 2 milliseconds.

Technical specifications

Frame

Construction of stainless steel 304.

Dimensions :

- Length : 4.383 mm

- Width : 2.646 mm

- Height : 2.900 mm

- Inspection belt width : 1.800 mm Netto

Water is needed for cleaning the belt (15 liters per minute, feed line for at least 3 /4 ")

Water pressure up to 2 bar, at least one bar

Belt speed control via frequency inverter

Airconditioner for constant temperature camera and computer cabinet

Power consumption : 8.5 kW

Power supply : 400 V AC, 3 phase + earth + neutral , 50 Hz

Computer Systems

Industrial setup

The system has an interface card for each camera with local processor

Graphic color control panel with IR touch screen operation (IP55)

Industrial computer enclosure with filtered fans

Cameras

4 pcs B / W CCD line scan type

Electronic compensation for offset drift of the camera signal

Software "offset " and " gain" settings

Software control of the camera signal

Software

Possible settings with " frame grag " and conventional method

Settings for color and shape recognition :

Color Recognition :

- In relative size of the head of the carrot

- Absolute spot size for the remainder of the carrot

Shape Recognition :

- Minimum and maximum length

- Length / width ratio

- Curvation

Product set-ups (pre-programmed)

Discharge unit

Electronic integrated in discharge unit

Air must be dried and 0.1 micron particles filtered, 3 degrees C dew point and 0.08 ppm ( 0.1 mg/m3 ) oil filtration

Air 6 bar minimum; consumes 1800 l / min at 30 % defect level

Air supply line at least 1 1/2 "

Lights

High frequency fluorescent lighting

IR illumination below the belt

Special reflectors for increased light output

Built- in camera body (less pollution)

Input vibrating screen

Dimensions:

- Length : 2,650 mm

- Width : 2,360 mm

- Height : 2,160 mm

Powered by unbalanced motors

Control cabinet et electric brake unit

Chute / ramp, equipped with special system to release the carrots on the belt

New price approx Euro 260.000,=

* Please ask for our very special sales price

Miért döntene a használt gép mellett?

- Gyorsan elérhető

- Kisebb beszerzési költség

- Alacsonyabb amortizációs költség

- Megegyező funkcionalitás

Gépek a következőre: Burgonya

Érdekli Ön ez a gép?

A következő lehetőségeket tudjuk felajánlani Önnek:

Árajánlatkérés

Kérem, küldjenek nekem árajánlatot erre a gépre.

Hozzá szeretném adni ezt a gépet kívánságlistámhoz, és tovább válogatnék.

Válassza ezt a lehetőséget, ha több gépre is szeretne árajánlatot kérni.

Van egy kérdésem erre a gépre vonatkozóan.

Érdekel ez a gép, de előbb egy kérdést szeretnék feltenni.

Are you interested in this machine?

We have the following options for you:

Request quote

Please send me a quote of this machine.

I want to add this machine to my request and look further.

Choose this option if you want a quotation on multiple machines.

I have a question about this specific machine.

I am interested in this machine but I want to ask a question first.

Ajánlatkérés (

Ajánlatkérés (

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)