English

English - Documents

Pros and cons

- Top occasion

- Hardly used

- High capacity

Description:

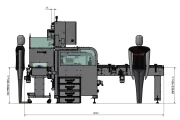

Bandall TRLS 24-25-77 banding machine double, fully automatically

This machine is standard equipped with the following options:

- Bandall banding unit

- Pneumatic side pusher

- Roll-near-end sensor

- Side roll holder

- Signal exchange and signal light

- Free-running roller conveyor as outfeed

- Servo motor-driven infeed pusher; easy to program

- Lexan safety casing

- Mounted on adjustable feet

- Stopper between external conveyor and infeed to separate continuous products

- IP65 control cabinet

- 2 boxes with parts

Additionally, this machine is equipped with the following extra options:

- 2x Multi-width mounting kit

- 2x Positioning system

- 2x External roll holder double buffer

- Printers & channel narrowing sets:

- 2x Novexx PEM printers

- 2x Bracket for printer

- 2x Multi-width channel narrowing set 77-62

- 2x Multi-width channel narrowing set 77-50

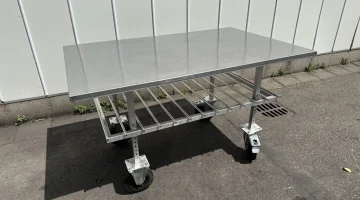

- Additional infeed conveyor:

- 125 x 30 cm

- Working height 95 cm

- Speed adjustable by frequency controller (controlled via PLC of automatic)

- 2 adjustable side guides

With these extra options, this machine is currently suitable for band widths of: 48, 60 and 75 mm.

The machine was previously used for avocados, mangoes and apples. This machine is also suitable for various other products.

Operation:

You feed the products/trays to be banded via the conveyor belt, after which the machine distributes them over the 2 banding units, placing the trays in the correct position to band the products as efficiently as possible. The machine can be adjusted for various sizes of products/trays, making it very versatile. By implementing this machine, you will save two full-time employees in your business process.

The capacity of the machine depends on the following aspects:

- Product size

- Product feeding direction

- Fragility of the product (how tightly the band can be applied)

- Type of band used (material and width)

If you would like to band a specific product, we need the above information to determine the precise capacity per minute.

Technical specifications:

| Model: | TRLS 24-25-77 |

| Condition | As good as new |

| Year: | 2023 |

| Capacity: | 25-40 pcs / minute |

| Transport dimensions: | 350 cm x 240 cm x 255 cm (length x width x height) |

| Transport weight: | 2000 kg |

| Input height: | 95 cm |

| Output height: | 95 cm |

Bandall TRLS 24-25-77 banding machine double, fully automatically

Price on request

Please contact Bas

We are happy to help. Our consultants are now waiting for you.

.jpg?resolution=100x100&quality=100&type=webp) Call us: +31 180 632 088

Call us: +31 180 632 088Keeping informed of similar machines?

Be the first to receive new additional machines in your mailbox with any of the following features.

Description:

This machine is standard equipped with the following options:

- Bandall banding unit

- Pneumatic side pusher

- Roll-near-end sensor

- Side roll holder

- Signal exchange and signal light

- Free-running roller conveyor as outfeed

- Servo motor-driven infeed pusher; easy to program

- Lexan safety casing

- Mounted on adjustable feet

- Stopper between external conveyor and infeed to separate continuous products

- IP65 control cabinet

- 2 boxes with parts

Additionally, this machine is equipped with the following extra options:

- 2x Multi-width mounting kit

- 2x Positioning system

- 2x External roll holder double buffer

- Printers & channel narrowing sets:

- 2x Novexx PEM printers

- 2x Bracket for printer

- 2x Multi-width channel narrowing set 77-62

- 2x Multi-width channel narrowing set 77-50

- Additional infeed conveyor:

- 125 x 30 cm

- Working height 95 cm

- Speed adjustable by frequency controller (controlled via PLC of automatic)

- 2 adjustable side guides

With these extra options, this machine is currently suitable for band widths of: 48, 60 and 75 mm.

The machine was previously used for avocados, mangoes and apples. This machine is also suitable for various other products.

Operation:

You feed the products/trays to be banded via the conveyor belt, after which the machine distributes them over the 2 banding units, placing the trays in the correct position to band the products as efficiently as possible. The machine can be adjusted for various sizes of products/trays, making it very versatile. By implementing this machine, you will save two full-time employees in your business process.

The capacity of the machine depends on the following aspects:

- Product size

- Product feeding direction

- Fragility of the product (how tightly the band can be applied)

- Type of band used (material and width)

If you would like to band a specific product, we need the above information to determine the precise capacity per minute.

Therefore used machines

- Quickly available

- Lower purchase costs

- Less amortization

- Same functionality

Comparable machines

Machines for Tomatoes

Are you interested in this machine?

We have the following options for you:

Request quote

Please send me a quote of this machine.

I want to add this machine to my request and look further.

Choose this option if you want a quotation on multiple machines.

I have a question about this specific machine.

I am interested in this machine but I want to ask a question first.

Request an offer (

Request an offer (

.jpg?resolution=720x400&quality=95&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.png?resolution=180x120&quality=90&type=webp)

.png?resolution=180x120&quality=90&type=webp)

.png?resolution=180x120&quality=90&type=webp)

.png?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)