Sorry this machine is already sold, but the following machines are available.

Ulma PV-350 flow packaging machine

Description:

Ulma PV-350 flow packaging machine

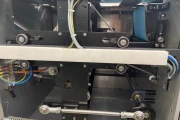

Ulma PV-350 flow packing machine with infeed conveyor

The Ulma PV 350 is designed for the packaging of loose difficult, delicate, and wet products. Such as leeks, carrots, peppers, Chinese cabbage, fennel, radish and even flowers like anthuriums.

- Top sealer

- Length indication sensor

- Suitable for unprinted foil

- Box motion cross seal

- Capacity up to 50 pieces per minute depending on the product

- Double film roll holder up to 1000 mm wide

- Digitally adjustable sealing temperature

- Self-adjusting adjustable folding cupboard

- Electronic speed control

- Temperature control for sealing bar and sealing rollers

- Input conveyor on the right side

- Built according to European directives / CE marking

- Digitial manual in English available. On request this can be send to you.

Product dimensions Ulma PV 350:

- Length: Min. 60 mm – till infinity by means of length indication photocell

- Width: Min. 10 mm – Max. 250 mm

- Heigth: Min. 10 mm – Max. 235 mm

- These machines work with BOPP film.

This machine is completely overhauled by Ulma in the Netherlands.

Invoice of this service can be send on request.

The following parts are renewed:

- Cutting knife

- Cutting rolls

- All conveyor belts

- All tension wheels

- All sprockets

- All bearings

- All bearing seal rollers

- Pneumatic hoses

- All drive chains

- Lots of new springs

- All plastic tension wheel

Ulma PV-350 flow packaging machine

Unfortunately, this Ulma PV-350 flow packaging machine has now been sold.

Would you like to be kept informed when a comparable Flow pack machines becomes available? Fill in your details here.

Sold

Please contact Sandré

We are happy to help. Our consultants are now waiting for you.

.jpg?resolution=100x100&quality=100&type=webp) Call us: +31 180 632 088

Call us: +31 180 632 088Description:

Ulma PV-350 flow packing machine with infeed conveyor

The Ulma PV 350 is designed for the packaging of loose difficult, delicate, and wet products. Such as leeks, carrots, peppers, Chinese cabbage, fennel, radish and even flowers like anthuriums.

- Top sealer

- Length indication sensor

- Suitable for unprinted foil

- Box motion cross seal

- Capacity up to 50 pieces per minute depending on the product

- Double film roll holder up to 1000 mm wide

- Digitally adjustable sealing temperature

- Self-adjusting adjustable folding cupboard

- Electronic speed control

- Temperature control for sealing bar and sealing rollers

- Input conveyor on the right side

- Built according to European directives / CE marking

- Digitial manual in English available. On request this can be send to you.

Product dimensions Ulma PV 350:

- Length: Min. 60 mm – till infinity by means of length indication photocell

- Width: Min. 10 mm – Max. 250 mm

- Heigth: Min. 10 mm – Max. 235 mm

- These machines work with BOPP film.

This machine is completely overhauled by Ulma in the Netherlands.

Invoice of this service can be send on request.

The following parts are renewed:

- Cutting knife

- Cutting rolls

- All conveyor belts

- All tension wheels

- All sprockets

- All bearings

- All bearing seal rollers

- Pneumatic hoses

- All drive chains

- Lots of new springs

- All plastic tension wheel

Therefore used machines

- Quickly available

- Lower purchase costs

- Less amortization

- Same functionality

Machines for Peppers

Are you interested in this machine?

We have the following options for you:

Request quote

Please send me a quote of this machine.

I want to add this machine to my request and look further.

Choose this option if you want a quotation on multiple machines.

I have a question about this specific machine.

I am interested in this machine but I want to ask a question first.

Request an offer (

Request an offer (

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=720x400&quality=95&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)