Pros and cons

- Top occasion

Description:

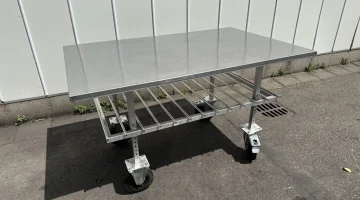

Visar stainless steel packing line with Netagco bin tipper and 16 weighing stations

Complete stainless-steel Visar packing line with Netagco bin tipper – 16 workstations

Very complete and professionally built stainless-steel weighing and packing line, designed for high capacity, efficient product handling and maximum operational reliability. This installation is highly suitable for intensive use within the fresh produce sector. (Previously used for carrots)

The line starts with a Netagco stainless-steel bin tipper, which ensures controlled and even product infeed. Via a stainless-steel elevator, the product is further processed within the fully stainless-steel packing line. Thanks to the smart layout and multiple transport and discharge options, the product flow remains continuous and well organized.

The packing line is equipped with 16 workstations (2 × 8 per side), each fitted with a bin rack and Siebert scale, enabling fast, accurate and ergonomic operation.

Composition of the line:

- Netagco stainless-steel bin tipper

- Stainless-steel elevator

- Complete stainless-steel packing line, consisting of:

- 2 packing belts

- Discharge conveyor for full bins

- Waste conveyor for rejected product with guide chute over the full length from the packing belts

- Waste discharge elevator

- Return elevator

- 16 workstations (8 per side) with bin rack and Siebert scale

Thanks to its fully stainless-steel construction, the line is durable, low-maintenance and easy to clean. An ideal solution for companies looking for a complete, efficient and future-proof packing line.

Operation: The tipper can be used to empty crates of product, which are then filled onto both packing belts via the wide conveyor belt. Any excess product falls onto the lower conveyor belt via a funnel at the end of the packing belts. This product is transported back to the front and the packing belts are refilled via the elevator. The lower conveyor belt is divided into two sections: one side is used for product returns as mentioned above, while the other side is for waste disposal. Employees manually throw the waste product onto this side via guide chutes, after which it is transported away from the packing belt via the other elevator at the front on the left-hand side.

Technical specifications:

| Model: | Visar |

| Condition | As good as new |

| Year: | 2017 |

| Transport dimensions: | 1360 cm x 230 cm x 200 cm (length x width x height) |

| Transport weight: | 2500 kg |

Visar stainless steel packing line with Netagco bin tipper and 16 weighing stations

Price on request

Please contact Reinier

We are happy to help. Our consultants are now waiting for you.

.jpg?resolution=100x100&quality=100&type=webp) Call us: +31 180 632 088

Call us: +31 180 632 088Keeping informed of similar machines?

Be the first to receive new additional machines in your mailbox with any of the following features.

Description:

Complete stainless-steel Visar packing line with Netagco bin tipper – 16 workstations

Very complete and professionally built stainless-steel weighing and packing line, designed for high capacity, efficient product handling and maximum operational reliability. This installation is highly suitable for intensive use within the fresh produce sector. (Previously used for carrots)

The line starts with a Netagco stainless-steel bin tipper, which ensures controlled and even product infeed. Via a stainless-steel elevator, the product is further processed within the fully stainless-steel packing line. Thanks to the smart layout and multiple transport and discharge options, the product flow remains continuous and well organized.

The packing line is equipped with 16 workstations (2 × 8 per side), each fitted with a bin rack and Siebert scale, enabling fast, accurate and ergonomic operation.

Composition of the line:

- Netagco stainless-steel bin tipper

- Stainless-steel elevator

- Complete stainless-steel packing line, consisting of:

- 2 packing belts

- Discharge conveyor for full bins

- Waste conveyor for rejected product with guide chute over the full length from the packing belts

- Waste discharge elevator

- Return elevator

- 16 workstations (8 per side) with bin rack and Siebert scale

Thanks to its fully stainless-steel construction, the line is durable, low-maintenance and easy to clean. An ideal solution for companies looking for a complete, efficient and future-proof packing line.

Operation: The tipper can be used to empty crates of product, which are then filled onto both packing belts via the wide conveyor belt. Any excess product falls onto the lower conveyor belt via a funnel at the end of the packing belts. This product is transported back to the front and the packing belts are refilled via the elevator. The lower conveyor belt is divided into two sections: one side is used for product returns as mentioned above, while the other side is for waste disposal. Employees manually throw the waste product onto this side via guide chutes, after which it is transported away from the packing belt via the other elevator at the front on the left-hand side.

Therefore used machines

- Quickly available

- Lower purchase costs

- Less amortization

- Same functionality

Comparable machines

Machines for Vegetables

Are you interested in this machine?

We have the following options for you:

Request quote

Please send me a quote of this machine.

I want to add this machine to my request and look further.

Choose this option if you want a quotation on multiple machines.

I have a question about this specific machine.

I am interested in this machine but I want to ask a question first.

Request an offer (

Request an offer (

.jpg?resolution=720x400&quality=95&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=180x120&quality=90&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)

.jpg?resolution=360x200&quality=85&type=webp)