Sorry this machine is already sold, but the following machines are available.

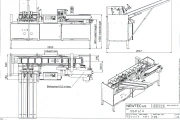

Newtec 2009A multihead weighing machine with NBM61A punnet filling machine

Description:

Newtec Type 2009A multihead weighing machine

Ideal machine for packing fruit of +/- 1 KG

- Suitable for apples, pears, stone fruit (plums, necatrines, peaches) clementines, kiwi fruit, tomatoes, cherrie tomatoes, brussels sprouts, potatoes and similar products.

- Gentle product handling with low drops

- Robustly constructed in stainless steel

- Pack weight programming in seconds

- Automatic taring

- Weighing max. 1,5 kg.

- 25-30 weighings per minute

- Year 1998

Complete with:

- Stainless steel elevator

- Greefa roller inspection conveyor

Newtec NBM61A punnet / container feeding and filling machine

- Suitable for stone fruit (plums, necatrines, peaches), kiwi fruit, mandarijen tomatoes, cherrie tomatoes, carrots and similar products.

- Capable to connect with one or two weighing machine.

- Double dispenser / denester for punnets:

- Punnet magazine, punnet separator, punnet stop plate, vacuum head, punnet sensor and transfer arm

- Punnet conveyor:

- Belt diveded with plates (vertical) as partitions for punnets.

- Belt vibrator for settling of product.

- Automatic filling

- Capacity 45 punnets per minute

- Complete with English manual

- Year 2006

The punnet machine should be continously fed with punnets via the punnet magazine. These punnets are let to the punnet conveyor by the dispencer. In the dispencer a punnet separator is positioned which ensures that only one punnet is taken at a time. Together with the punnet separator there is a stop plate wich holds all the remaining punnets while the separator is working. The vacuum head brings the punnets down on a support plate, so that the transfer arm can dispense the punnet into position on the punnet conveyor.

The punnet machine controls the weighing machine by signalling to it when ready to receive a portion. Then the conveyor dispenses the product into the collection conveyor that fills the punnet. When the punnet is filled the belt vibrates to settle the product.

Finally the transfer arm dispenses the filled punnet out of the machine on a conveyor. This conveyor can be connected to a packaging machine.

Optional: The Newtec 2009 weighing machine could also work with the following: Burg BTV 2000 bag filling machine for fruit, such as apples

Technical specifications:

| Model: | 2009A & NBM61A |

| Year: | 1998 & 2006 |

| Capacity: | 25-30 weighing / minute. Max 1,5 kg |

| Dimensions: | 730 cm x 360 cm (length x width) |

Newtec 2009A multihead weighing machine with NBM61A punnet filling machine

Unfortunately, this Newtec 2009A multihead weighing machine with NBM61A punnet filling machine has now been sold.

Would you like to be kept informed when a comparable Weighing machine becomes available? Fill in your details here.

Sold

Please contact Reinier

We are happy to help. Our consultants are now waiting for you.

(2).jpg?resolution=100x100&quality=100&type=webp) Call us: +31 180 632 088

Call us: +31 180 632 088Description:

Newtec Type 2009A multihead weighing machine

Ideal machine for packing fruit of +/- 1 KG

- Suitable for apples, pears, stone fruit (plums, necatrines, peaches) clementines, kiwi fruit, tomatoes, cherrie tomatoes, brussels sprouts, potatoes and similar products.

- Gentle product handling with low drops

- Robustly constructed in stainless steel

- Pack weight programming in seconds

- Automatic taring

- Weighing max. 1,5 kg.

- 25-30 weighings per minute

- Year 1998

Complete with:

- Stainless steel elevator

- Greefa roller inspection conveyor

Newtec NBM61A punnet / container feeding and filling machine

- Suitable for stone fruit (plums, necatrines, peaches), kiwi fruit, mandarijen tomatoes, cherrie tomatoes, carrots and similar products.

- Capable to connect with one or two weighing machine.

- Double dispenser / denester for punnets:

- Punnet magazine, punnet separator, punnet stop plate, vacuum head, punnet sensor and transfer arm

- Punnet conveyor:

- Belt diveded with plates (vertical) as partitions for punnets.

- Belt vibrator for settling of product.

- Automatic filling

- Capacity 45 punnets per minute

- Complete with English manual

- Year 2006

The punnet machine should be continously fed with punnets via the punnet magazine. These punnets are let to the punnet conveyor by the dispencer. In the dispencer a punnet separator is positioned which ensures that only one punnet is taken at a time. Together with the punnet separator there is a stop plate wich holds all the remaining punnets while the separator is working. The vacuum head brings the punnets down on a support plate, so that the transfer arm can dispense the punnet into position on the punnet conveyor.

The punnet machine controls the weighing machine by signalling to it when ready to receive a portion. Then the conveyor dispenses the product into the collection conveyor that fills the punnet. When the punnet is filled the belt vibrates to settle the product.

Finally the transfer arm dispenses the filled punnet out of the machine on a conveyor. This conveyor can be connected to a packaging machine.

Optional: The Newtec 2009 weighing machine could also work with the following: Burg BTV 2000 bag filling machine for fruit, such as apples

Therefore used machines

- Quickly available

- Lower purchase costs

- Less amortization

- Same functionality

Machines for Tomatoes

Are you interested in this machine?

We have the following options for you:

Request quote

Please send me a quote of this machine.

I want to add this machine to my request and look further.

Choose this option if you want a quotation on multiple machines.

I have a question about this specific machine.

I am interested in this machine but I want to ask a question first.

Request an offer (

Request an offer (

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)

.jpg?resolution=360x200&quality=95&type=webp)